0 to 60: Steering Automotive Operations With RPA

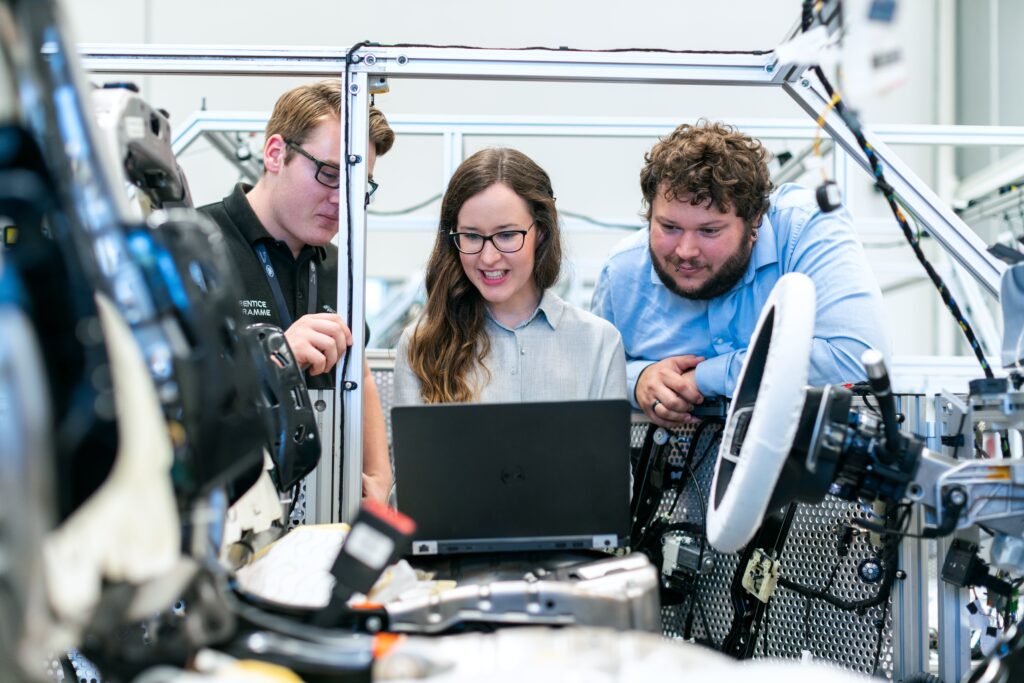

In an era where technological advancements shape industries, the automotive sector is experiencing a transformative wave with the integration of Robotic Process Automation (RPA) and Microsoft Power Platform. This powerful combination has proven to be a game-changer for industry leaders such as ZF Group and Toyota, offering a plethora of benefits ranging from cost reduction and error elimination to enhanced employee experience and competitive advantage.

Microsoft Power Platform in the Automotive Industry:

The Microsoft Power Platform, embraced by giants like ZF and Toyota, is a suite of business intelligence, app development, and automation tools designed to significantly lower costs, reduce human errors, and enhance overall operational efficiency. With success stories like ZF’s deployment of more than 42,000 Power Platform solutions, the industry is witnessing a shift towards a more streamlined and agile approach.

ZF Group Case Study:

ZF Group, a global automotive technology supplier with over 150,000 employees, adopted the Power Platform as part of its Microsoft 365 launch. The results were astounding, with more than 200,000 Power Platform activities discovered across the organization. The implementation not only enabled lean manufacturing reporting but also saved over 1,500 hours annually in manual data processing.

The IoP project at ZF unveiled the necessity for controlled development processes. A tiered environment structure and Data Loss Prevention (DLP) policies were introduced to manage premium connectors efficiently. The “Spot Assessment,” an automated form built using Power Automate, further ensured collaboration between the central team and citizen developers for optimal app development.

Toyota’s No-Code Revolution:

Toyota Motor North America (TMNA), headquartered in Plano, Texas, adopted a no-code and low-code development approach using Microsoft Power Platform. With a focus on respecting people and fostering innovation, TMNA empowered its employees to turn ideas into over 400 active apps. The Center of Excellence at TMNA played a pivotal role in providing training and support, creating knowledge ambassadors within the organization.

RPA in Automotive: What Exactly is it?

Robotic Process Automation (RPA) serves as the ideal companion to Microsoft Power Platform, automating repetitive, time-consuming tasks traditionally performed by humans. Whether it’s handling supplier contracts, logging service reports, or managing order processing, RPA ensures error elimination, scalability, increased efficiency, and substantial cost savings.

Real-World Applications of RPA in Automotive:

The automotive industry presents numerous opportunities for RPA implementation, such as optimizing inventory management, automating malfunctions notifications, incorporating analytics into marketing and sales, and streamlining order submission processes. The real-world scenarios outlined, from expense approval automation to customer appointment scheduling, highlight the versatility and effectiveness of RPA.

Market Trends and Growth Projections:

The market size for automation in the automotive industry is projected to experience a Compound Annual Growth Rate (CAGR) of 32% from 2023 to 2029. Industrial robots on assembly lines and the integration of RPA in diverse operations signify a significant expansion in the adoption of automation technologies, emphasizing the industry’s commitment to efficiency, reliability, and cost-effectiveness.

All in all, the convergence of RPA and Microsoft Power Platform is steering the automotive industry towards unprecedented efficiency, innovation, and competitiveness. Case studies from ZF and Toyota exemplify the transformative power of these technologies. As the market continues to grow, embracing RPA and Power Platform becomes imperative for automotive companies aiming to stay ahead in an era of digital evolution. The future of automotive operations is now, driven by the seamless synergy of cutting-edge technologies.

* Source: Customers.Microsoft.com